“Sharps” must cut cleanly (resharpen if needed) and close properly. Check for burrs along the cutting edges. Needle holders and clamps must engage properly and meet correctly at the tips.

Newly purchased instruments must be cleaned, lubricated and autoclaved before use.

Instruments are designed for a particular purpose and should be used only for that purpose. Even the strongest instrument can be damaged when used inappropriately, such as when scissors are used to cut wire.

Regular tap water contains minerals that can cause discoloration and staining. We recommend using distilled water for cleaning, disinfecting, sterilizing and rinsing. To avoid staining, use a cleaning solution with a pH near neutral (7). Instruments should be placed in distilled water immediately after use. They should never be placed in saline solution, as it may cause corrosion and eventually irreversible damage to the instrument.

When handling instruments, be careful not to damage fine tips and mechanisms. If instruments have been exposed to blood, tissue, saline or other foreign matter, they must be rinsed in warm water before these substances are allowed to dry. Failure to do so may cause rusting. After rinsing, immerse them in a cleaning and disinfecting solution.

Because many compounds, including certain chemicals, are highly corrosive to stainless steel, rinse and dry instruments immediately if they come into contact with any potentially harmful substances. If no ultrasonic cleaner is available, clean the instrument very carefully. Pay particular attention when cleaning box locks, serrations, hinges and other hard-to-reach areas. Use nylon (not steel) brushes and warm (not hot) cleaning solutions. Follow the manufacturer’s instructions for the preparation of the cleaning solutions. Change these solutions daily.

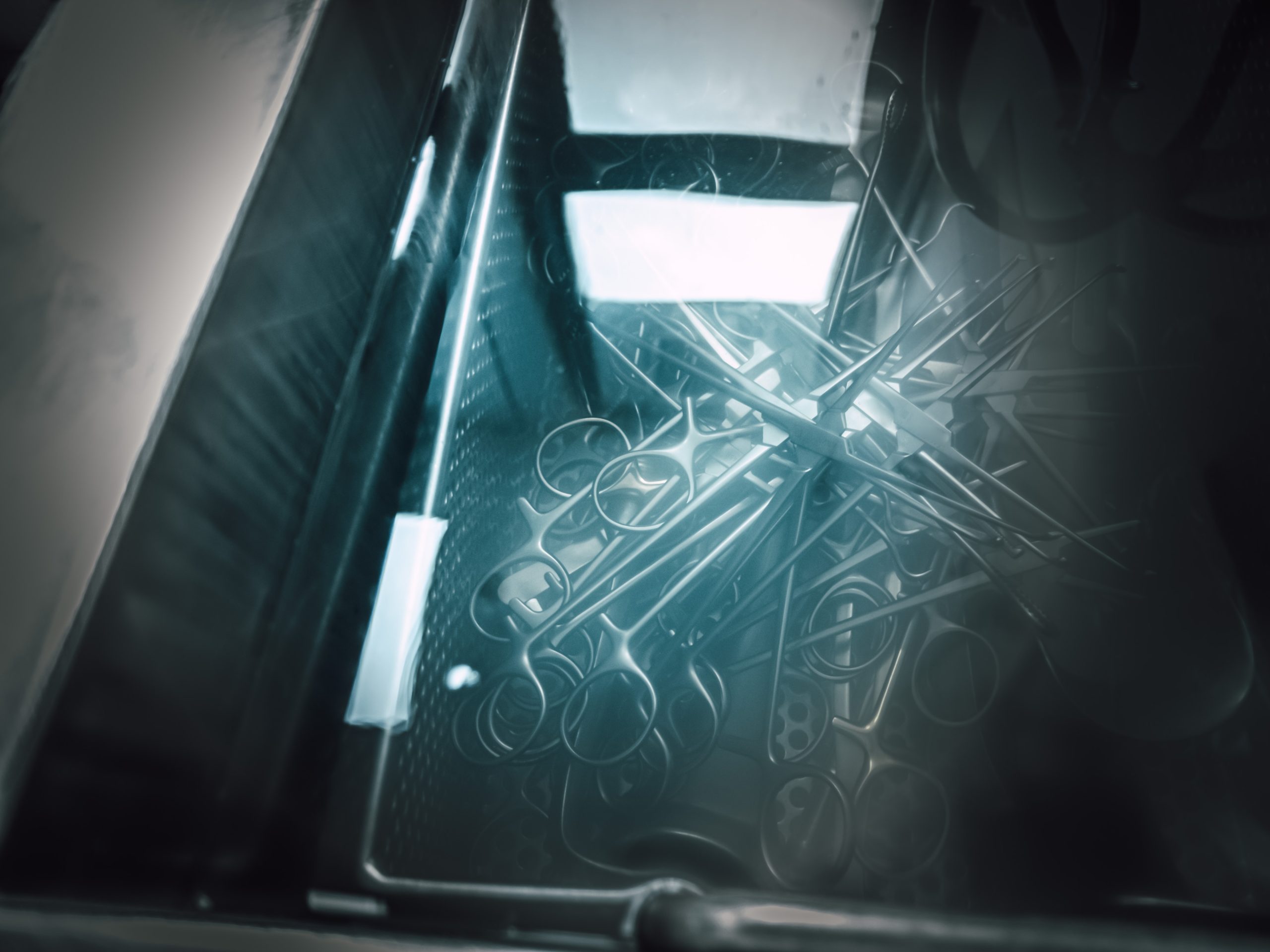

Ultrasonic cleaning is the most effective and efficient way to clean instruments. To maximize its effectiveness, instruments should be cleaned of all visible debris before they are placed in an ultrasonic cleaner.

When using ultrasonic cleaners:

The best time to review the condition of instruments is after they have been cleaned, lubricated and before sterilization. Check for:

“Sharps” must cut cleanly (resharpen if needed) and close properly. Check for burrs along the cutting edges. Needle holders and clamps must engage properly and meet correctly at the tips.

Inspect surfaces for any sign of staining, cracking or other irregularities. Common sources of staining are:

All instruments must be properly cleaned before autoclaving. Moving parts, such as box locks and hinges, should be well lubricated. Be sure to use surgical lubricants and not industrial oils.

Always sterilize instruments in the open, unlocked position.

We recommend that instruments be wrapped in cloth and then placed in the container, or that a cloth be put on the bottom of the pan to absorb moisture. The cloth should be pH(7) neutral and free of detergent residues.

Please note that chrome-plated instruments may rust if they are not dried and lubricated immediately after sterilization.

Finally, avoid sudden cooling. Instruments should be allowed to air-dry.

Prolonged immersion in disinfecting or sterilizing solution can damage surgical instruments. Do not soak instruments for longer than 20 minutes. To render the instruments sterile and ready for use, we recommend using an autoclave.

Instruments with tungsten carbide, such as wire cutters, needle holders and TC scissors, should never be immersed in sterilizing solutions containing benzyl ammonium chloride (BAC). BAC will soften and dissolve the tungsten carbide. Never use bleach as it will cause severe pitting.

Once instruments are thoroughly dry, store them in a clean, dry environment. Never put them in areas where chemicals may emit corrosive vapors or where temperature and moisture variations could cause condensation on the instruments.